FANUC’s AI Servo Monitor provides machine health data and analysis to maximize uptime.

Downtime is the enemy of profitability in manufacturing, which is why FANUC, a leading global automation solutions provider, has introduced a new Industrial Internet of Things (IIOT) software designed to prevent production problems before they happen. AI Servo Monitor uses artificial intelligence to predict possible failures of the drive systems for FANUC servomotors and spindle motors.

“The power of IIOT software is that it detects a failure before it happens, not after”

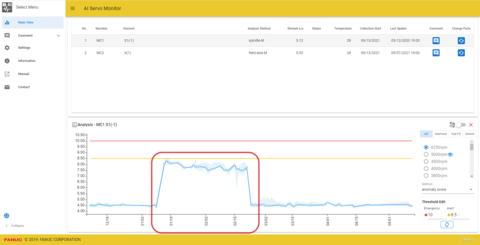

AI Servo Monitor, in conjunction with MT-LINKi through machine learning, analyzes the daily performance of machines equipped with FANUC CNCs. Daily data is displayed in intuitive graphs which allows users to easily monitor abnormalities on these machines. Artificial intelligence automatically creates a baseline model of the machine while running in a normal state. An “anomaly score” developed expresses a difference in the baseline model and the daily recorded values. On a web interface, users can easily see the anomaly scores in a graph. Plus, email notifications can be issued if this value exceeds the predefined thresholds.

Latest ITechnology News: Contrast Security Named a JMP Securities Elite 80 Cybersecurity Company

“The power of IIOT software is that it detects a failure before it happens, not after,” says Jon Heddleson, General Manager of Factory Automation for FANUC America. “Predictive maintenance is key in preventing unexpected downtime. FANUC’s AI Servo Monitor helps ensure that production keeps running smoothly.”

MT-Linki is FANUC’s machine status monitoring and data collection software that connects shop floor equipment, including machine tools, robots and PLCs. MT-Linki monitors, collects, and presents data in color-coded graphical representations of the factory floor to provide more information about manufacturing processes as well as historical data. Non-FANUC CNCs, PLCs and various sensors can be connected using MTConnect or OPC-UA protocol.

Latest ITechnology News: Aramco and Cognite Join Forces in New Data Venture

Information presented via MT-Linki enables data-driven business decisions to optimize operations through enhanced maintenance capabilities such as scheduling memory backups, presenting alarm/operator history, and monitoring the status of memory backup batteries, cooling fans, motor temperatures, etc.

Latest ITechnology News: BlastWave Unifies Remote Cloud Security with Bulk Onboarding and Login Convenience Through BlastShield Software Update

[To share your insights with us, please write to sghosh@martechseries.com]